I. Product Overview

Polyacrylic Acid Potassium (KPAM) Drilling Fluid Additive

Optimized for High-Performance Drilling Operations

Potassium polyacrylate (K-PAM) is anionic polymer additive engineered to optimize drilling fluid performance in complex geological conditions that is a multi-component copolymer used as an anti collapse agent in freshwater and saltwater drilling fluids. Its appearance is a white or light yellow powder.

Manufactured by Beijing Sanhe Runjing Technology Co., Ltd., a leader in drilling fluid innovation, KPAM excels in stabilizing wellbores, mitigating shale hydration, and enhancing overall drilling efficiency. Its advanced molecular structure ensures compatibility with both water-based and saltwater-based mud systems.

Phone: +86 010-56674877 +86 17326821931 (TEL )

whatsapp: 17326821931 Wechat: 13716268431

II. Functions and Characteristics

Key Technical Advantages

Strong Flocculation: Facilitates the removal of inferior solids such as rock dust.

Strong Shale Inhibition: Effectively prevents drilling fluid-induced shale collapses.

Fluid Loss Reduction: Demonstrates a certain degree of fluid loss reduction in drilling fluids.

High Molecular Weight: With a molecular weight exceeding 12 million.

Mechanism: Forms a hydrophobic film on shale surfaces via ionic bonding, effectively blocking water ingress and preventing clay swelling.

Action: Coats drill cuttings with a polymer layer, minimizing fragmentation and reducing torque/drag risks.

Benefit: Improves fluid clarity and stabilizes rheological properties under high-temperature conditions

Environmental Compliance

Biodegradability: eco-safe drilling operations.

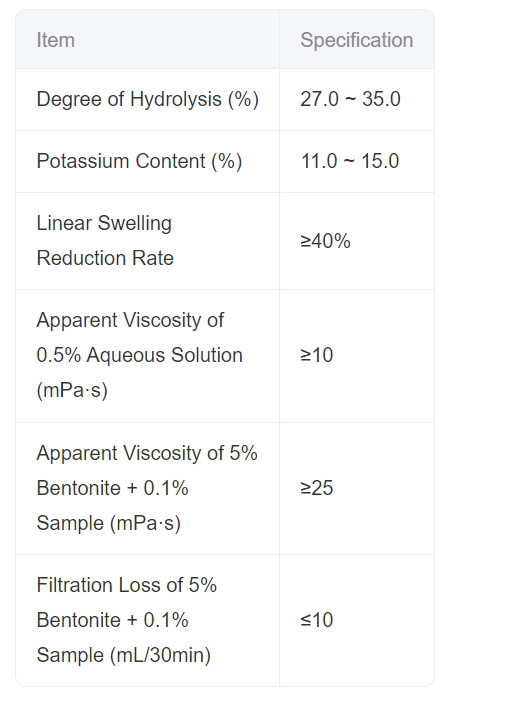

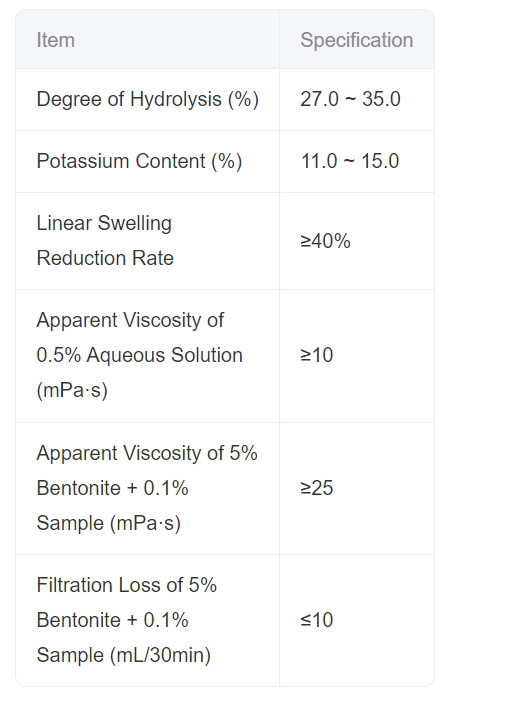

III. Technical Specifications

Application Scope

Polypotassium Acrylate can be widely used in both freshwater and saltwater drilling fluid systems.

Recommended Dosage

Freshwater Mud: Recommended dosage is 0.05% to 0.1%.

Saltwater Mud: Recommended dosage is 0.2% to 0.7%.

The actual dosage may vary depending on the specific application environment.

Optimal dosage should be determined based on specific well conditions and drilling parameter

Recommended Applications

Shale Formations: Prevents wellbore collapse in water-sensitive strata (e.g., Montney, Haynesville).

High-Temperature Wells: Stabilizes fluid viscosity in geothermal and deep reservoirs.

Saltwater Systems: Compatible with NaCl/CaCl₂ brines up to saturation.

Horizontal Drilling: Reduces friction coefficient by 30–40% in extended-reach wells.

IV.Packaging & Storage

Packaging: 25 kg triple-layer kraft bags

Storage Conditions:

Keep dry and protect from direct sunlight and moisture.

Temperature: 10–30°C (avoid thermal cycling).

Humidity: ≤65% RH (critical for anti-caking).

Ventilation: Well-ventilated area, isolated from oxidizers.

Validity Period: 24 months from production date (see batch code for details).

Additional Details:

Versatile Application: The product adaptability allows it to be tailored for different drilling scenarios, ensuring optimal performance and cost-effectiveness.

Disclaimer: The above information is provided for reference only. Actual performance may vary based on specific drilling conditions and operational practices. Please consult with technical experts for detailed application guidance.