1. Product Overview

Carboxymethyl Cellulose – High Viscosity (HV-CMC) is mainly used as a viscosity enhancer for freshwater or saltwater drilling fluids. It appears as a white or pale yellow powder.

HV-CMC is a high-performance cellulose derivative engineered for complex drilling conditions (e.g., HPHT, water-sensitive shale). With ultra-high viscosity, it enhances cuttings transport efficiency and wellbore stability, ideal for onshore/offshore deep wells, horizontals, and shale gas operations.

whatsapp: 17326821931 Wechat: 13716268431

2. Functions and Characteristics

(1)Functions and Characteristics

It can effectively increase the viscosity of the drilling fluid.

It can effectively reduce the fluid loss of the drilling fluid.

It has a certain ability to resist salt. The product is non-toxic, biodegradable, and has good environmental protection performance.

- Effectively increases the viscosity of drilling fluids.

- Effectively reduces the water loss of drilling fluids.

- Possesses certain salt resistance capabilities.

Non-toxic, degradable, and environmentally friendly.

(2) Key Features & Advantages

✅ Superior Viscosity

✅ Precision Fluid Loss Control

✅ Eco-Friendly & Compatibility

(3)Application Scope

Widely applicable in freshwater and saltwater drilling fluid systems.

Recommended Dosage

- Freshwater Mud Recommended Dosage: 0.1~5%.

- Saltwater Mud Recommended Dosage: 1.0~0%.

Adjustments: The actual dosage may vary depending on the specific drilling conditions and environmental factors .Optimal dosage should be determined based on specific well conditions and drilling parameter

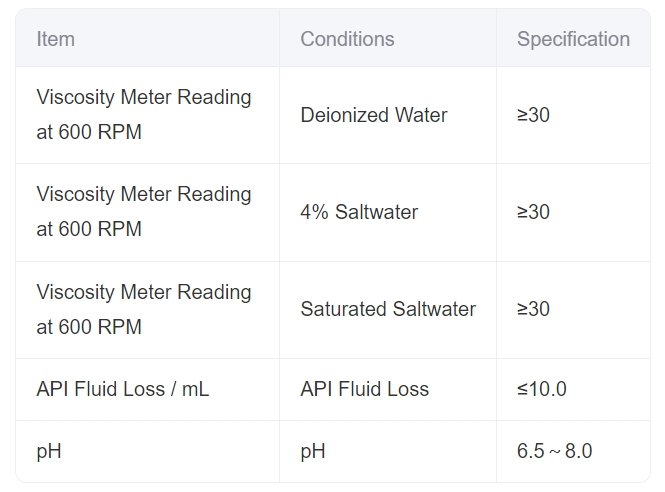

4.Technical Specifications

It can be widely used in both freshwater and saltwater drilling fluid systems.

5.Packaging & Storage

Packaging: 25 kg triple-layer kraft bags

Storage Conditions:

Keep dry and protect from direct sunlight and moisture.

Temperature: 10–30°C (avoid thermal cycling).

Humidity: ≤65% RH (critical for anti-caking).

Ventilation: Well-ventilated area, isolated from oxidizers.

Validity Period: 24 months from production date (see batch code for details).

6.Additional Details:

Versatile Application: The product adaptability allows it to be tailored for different drilling scenarios, ensuring optimal performance and cost-effectiveness.

Disclaimer: The above information is provided for reference only. Actual performance may vary based on specific drilling conditions and operational practices. Please consult with technical experts for detailed application guidance.