1.Dissolution-prone Formations

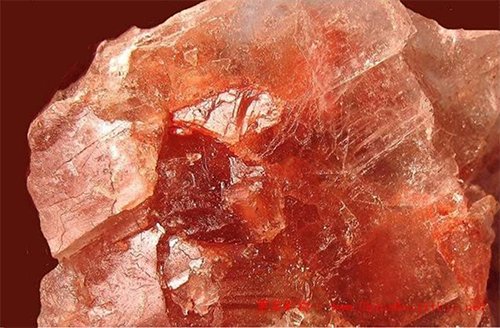

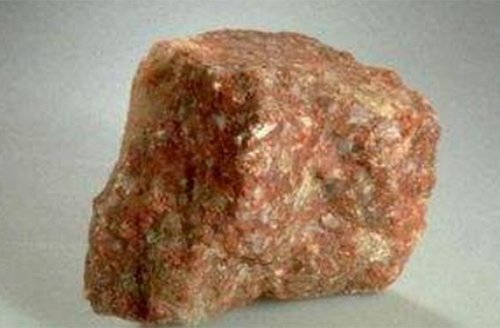

Dissolution-prone formations refer to those containing soluble salts or alkalis. When encountering water in the drilling fluid, these substances dissolve, causing the well wall to erode. Halite and sylvite are the most typical examples. Halite mainly consists of potassium and magnesium halides; sylvite is a non-metallic mineral primarily composed of potassium chlorides and sulfates.

-2.jpg&w=150;&h=150;&zc=1)

.jpg&w=150;&h=150;&zc=1)

2.Problems Encountered during Drilling Operations

(1) Hole Enlargement

The most common problem when drilling through dissolution-prone formations is that the formation’s rock matrix dissolves when exposed to water, leading to an enlarged hole diameter.

(2) Poor Core Quality

Due to the dissolution of rock cores in water, they are prone to dissolving, resulting in poor core quality and a decrease in core recovery rate.

(3)Increase in drilling fluid water loss and thickening of mud cake: When salt intrusion reaches a certain level, the dispersion of clay decreases, leading to stratification of the drilling fluid, further increase in water loss, and thickening of the mud cake. The rate decreases.

(4) Corrosion of drilling tools: Soluble salts are electrolytes, and after prolonged contact with drilling tools, electrochemical corrosion is prone to occur, affecting the lifespan of the drilling tools.

3.Measures for Drilling in Soluble Formations

For soluble formations, measures should be taken from two main aspects:

(1)Reducing the dissolution of the formation by water in the drilling fluid,

(2)Reducing the fluid loss of the drilling fluid.

(3)Reducing the dissolution of the formation by the drilling fluid: Generally, salts similar to those in the formation are used to prepare the drilling fluid. For example, for carnallitite formations, a composite salt system is employed.

4.Reducing fluid loss:

To reduce the fluid loss of saline drilling fluids, salt-resistant fluid-loss additives should be used. (Insert relevant company products.)

5.Adding corrosion inhibitors:

Corrosion inhibitors should be added to the drilling fluid to reduce or slow down the corrosion of drilling tools by the drilling fluid. (Insert relevant company products.)

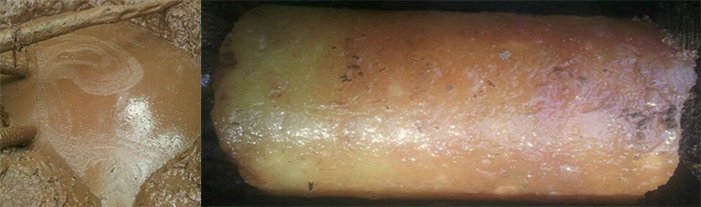

4.Application Cases

Strong Inhibition Drilling Fluid and Extracted Rock Core Containing Sylvite Ore.

.jpg&w=150;&h=150;&zc=1)

.jpg&w=150;&h=150;&zc=1)

.jpg&w=150;&h=150;&zc=1)

.jpg&w=150;&h=150;&zc=1)