1.Product Introduction

HTFT is an anti-collapse and plugging material specifically engineered for high-temperature water-based drilling fluid systems. Composed of fibrous materials, rigid ions, and deformable cementing materials, it is available in a series of products tailored to meet various temperature resistance requirements. HTFT appears as a black, free-flowing powder.

2.Functions and Characteristics

Cold Water Dispersibility: Effectively inhibits shale hydration expansion.

Cementation & Plugging: Contributes to wellbore stability with excellent cementation and plugging properties.

Lubrication: Prevents sticking and bit locking due to its good lubrication performance.

Rheological Properties: Maintains good mud rheological properties without increasing viscosity.

Temperature Customization: Offers customizable products based on specific temperature resistance needs.

Primary Functions

High-Temperature Stabilization

Prevents wellbore instability caused by high temperatures.

Fracture Sealing

Seals fractures and micro-fractures within the wellbore.

Clay Hydration Inhibition

Reduces the risk of shale hydration and resultant wellbore collapse.

Drilling Efficiency Enhancement

Improves drilling efficiency by reducing torque and drag.

3.Technical Indicators

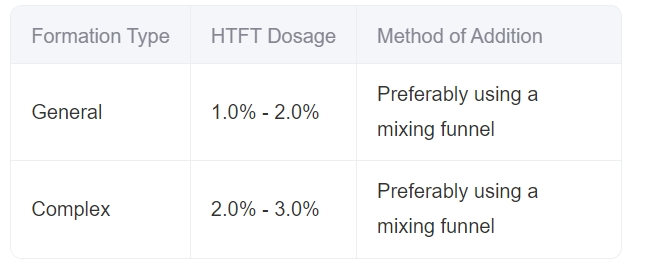

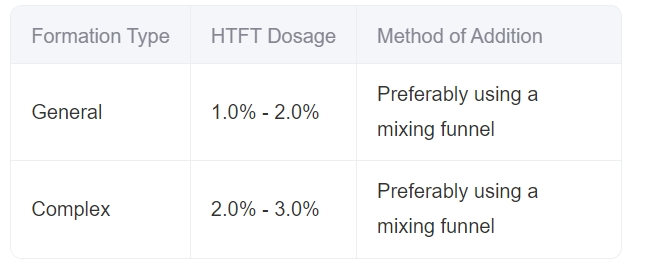

Operational Guidelines

Preparation: Ensure the base drilling fluid is properly circulated before adding HTFT.

Dosage Adjustment: Adjust the dosage according to the specific geological conditions and drilling fluid performance.

Mixing: Gradually add HTFT to the drilling fluid using a mixing funnel while maintaining agitation to ensure even distribution.

It is advisable to conduct laboratory tests or field trials to determine the optimal dosage for specific drilling operations.

4.Packaging & Storage

Packaging: 25 kg triple-layer kraft bags

Storage Conditions:

Keep dry and protect from direct sunlight and moisture.

Validity Period: 24 months from production date (see batch code for details).

Additional Details:

Versatile Application: The product adaptability allows it to be tailored for different drilling scenarios, ensuring optimal performance and cost-effectiveness.

Disclaimer: The above information is provided for reference only. Actual performance may vary based on specific drilling conditions and operational practices. Please consult with technical experts for detailed application guidance.

-1.jpg&w=440;&h=440;&zc=1)

2.jpg&w=440;&h=440;&zc=1)

-1.jpg&w=80;&h=80;&zc=1)

2.jpg&w=80;&h=80;&zc=1)

2.jpg)