1.Product Introduction

Hydroxypropyl guar gum (HPG) is chemically modified from natural bean powder. It has excellent salt resistance and thixotropy, and appears as a white or light yellow powder.

2.Functions and Characteristics

(1)

- It can significantly increase the viscosity and shear force of the mud, and has a strong ability to suspend and carry sand.

- It has good compatibility and can be used in combination with other mud materials.

- It is degradable, non-toxic, and pollution-free, which is conducive to environmental protection.

(2)Key Features & Advantages

- Superior Viscosity Control: Rapidly adjusts rheological properties to maintain shear resistance.

- Thermal Stability: Retains performance in high-temperature environments (up to 180°C), ideal for deep wells and dry hot rock exploration.

- Salt Tolerance: Effective in saline or seawater-based fluids, preventing viscosity degradation.

- Environmental Compliance: Biodegradable formula reduces ecological risks

(3)Core Functions

Enhances Cuttings Transport: Boosts carrying capacit in high-density mud systems.

Reduces Fluid Loss:

Prevents Wall Collapse: Forms a protective film in loose/fractured formations.

Synergistic Compatibility: Integrates seamlessly withplugging agents (GPC) andmodified asphalt (GLA) for enhanced sealing and lubrication.

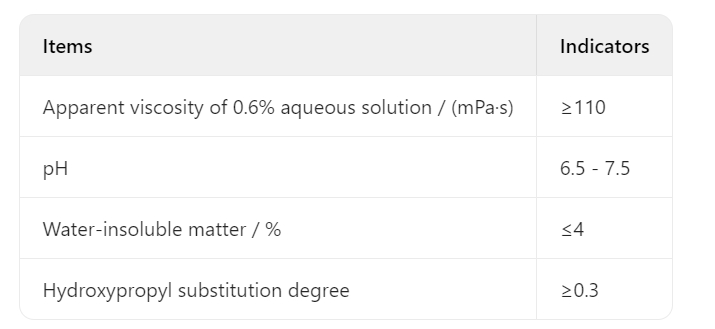

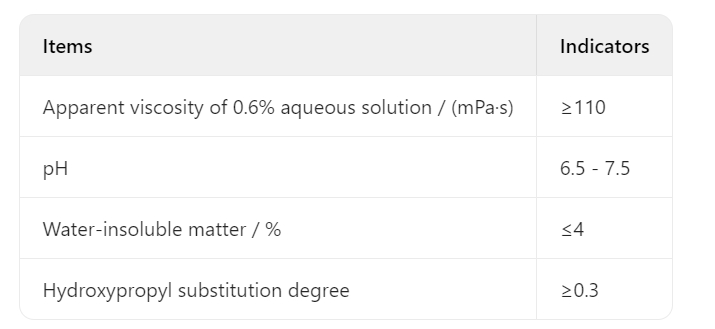

3.Technical Indicators

4.Application Scope

It can be widely used in fresh water and salt water drilling fluid systems.

5.Recommended Dosage

- Recommended dosage for fresh water drilling fluid: 0.2 – 0.5%.

- Recommended dosage for salt water drilling fluid: 0.5 – 1.0%.

- The actual dosage of the treatment agent may vary according to the use environment.

6.Packaging & Storage

Packaging: 25 kg triple-layer kraft bags

Storage Conditions:

Keep dry and protect from direct sunlight and moisture.

Temperature: 10–30°C (avoid thermal cycling).

Humidity: ≤65% RH (critical for anti-caking).

Ventilation: Well-ventilated area, isolated from oxidizers.

Validity Period: 24 months from production date (see batch code for details).

Additional Details:

Versatile Application: The product adaptability allows it to be tailored for different drilling scenarios, ensuring optimal performance and cost-effectiveness.

Disclaimer: The above information is provided for reference only. Actual performance may vary based on specific drilling conditions and operational practices. Please consult with technical experts for detailed application guidance.

.jpg&w=440;&h=440;&zc=1)

2.jpg&w=440;&h=440;&zc=1)

.jpg&w=80;&h=80;&zc=1)

2.jpg&w=80;&h=80;&zc=1)

2.jpg)